Concrete Slab Scanning: What You Need to Know

Smart project planning means accounting for the unknowns, especially those buried just beneath the surface. Integrating concrete slab scanning into your project from the beginning is a strategic move that prevents surprise discoveries that lead to costly delays and change orders. When you know exactly what’s inside a slab before the coring rig shows up, you can plan your work with confidence. This proactive approach allows you to map out core locations and trench paths around critical infrastructure instead of reacting to it. It transforms scanning from a simple damage-prevention task into a powerful planning tool that keeps your project moving forward smoothly.

Key Takeaways

- Treat Scanning as Essential Risk Management: Before cutting or coring, a GPR scan is the most effective way to prevent dangerous utility strikes, avoid costly structural damage, and keep your project on schedule and within budget.

- Turn Guesswork into a Clear Plan: GPR technology creates a detailed map of everything hidden in the concrete—from rebar and post-tension cables to electrical conduits. This data allows you to plan core and cut locations with precision, eliminating surprises.

- Prioritize Proven Expertise for Reliable Data: The most advanced GPR equipment is only as good as the technician interpreting its signals. Partner with an experienced crew that can accurately distinguish between different subsurface objects to ensure the data you receive is clear and trustworthy.

What Is Concrete Slab Scanning?

Before you cut, core, or drill into a concrete slab, you need to know what’s hidden inside. Concrete slab scanning is a non-destructive process that gives you a clear picture of the rebar, conduits, and utilities embedded within the structure. Think of it as creating a detailed map of your slab without any harmful radiation or damage. This crucial first step helps you avoid dangerous and expensive mistakes, like hitting a live electrical line, damaging a post-tension cable, or compromising the building's structural integrity. It’s the modern, safe alternative to guesswork and blind drilling.

Using Ground Penetrating Radar (GPR), a trained technician can evaluate the concrete and locate potential hazards before your crew ever starts work. This isn’t just about finding one or two pipes; it’s about understanding the entire subsurface environment to ensure a smooth project. Whether you’re planning to trench for new fiber optic lines, install plumbing, or perform structural upgrades, scanning provides the critical data you need. It’s the most reliable way to protect your crew, your budget, and your timeline from unforeseen obstacles lurking just beneath the surface. Our comprehensive subsurface utility mapping gives you the confidence to proceed, knowing exactly what you’re dealing with. By identifying the precise location and depth of embedded objects, you can plan your cuts and cores with surgical precision, preventing costly repairs and dangerous accidents.

How GPR Technology Works

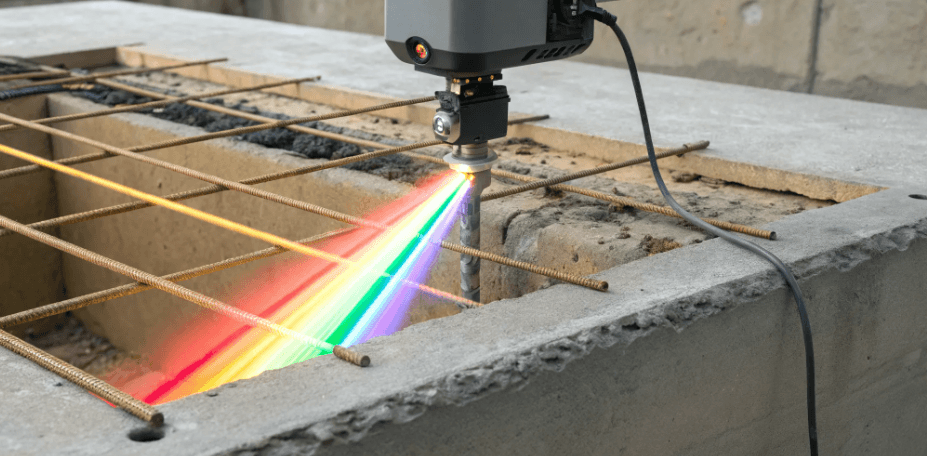

Ground Penetrating Radar (GPR) might sound complex, but the concept is pretty straightforward. The equipment sends harmless, high-frequency radio waves into the concrete. When these waves encounter an object with different properties than the surrounding concrete—like steel rebar, a PVC conduit, or even an air void—they bounce back to a receiver. Different materials reflect the waves in unique ways, creating a distinct signature that appears as an image on the technician’s screen. An experienced operator can interpret these signals to identify not just what’s inside the slab, but also its size, shape, and depth with remarkable accuracy.

The Step-by-Step Scanning Process

When we arrive on-site, our process is efficient and methodical to minimize disruption to your project. First, we prepare the area by clearing it of any surface debris or equipment. Then, we mark a clear grid on the concrete surface, which ensures we get complete, systematic coverage of the entire scan area. Our technician then pushes the GPR antenna across the grid lines, collecting data with each pass. The results appear on a screen in real-time, allowing for immediate interpretation. As we identify targets, we mark their location and depth directly on the slab with chalk, wax, or spray paint, giving your crew a clear visual guide.

Common Myths vs. Reality

There are a few common misconceptions about concrete scanning that are worth clearing up. Many people think GPR can see everything with perfect clarity, but that’s not quite true.

Myth: GPR is like an X-ray and can see everything. Reality: While powerful, GPR has limitations. Extremely thick concrete, high moisture content, or tightly spaced rebar can make data harder to interpret. This is why having an expert technician is so important—they know how to read complex signals and understand the technology’s limits.

Myth: GPR scanning is dangerous. Reality: Unlike X-rays, GPR uses safe radio waves. There’s no radiation involved, so your site can continue operating without any safety concerns while we work. Our utility locating services are designed to be non-invasive and safe for everyone on site.

What Can Concrete Scanning Find?

Before you cut, core, or drill, you need to know what’s hidden inside the concrete. Making assumptions is a recipe for dangerous and expensive mistakes. Concrete scanning uses Ground Penetrating Radar (GPR) to create a detailed map of what lies beneath the surface, giving your team a clear path forward. Think of it as a non-destructive way to get x-ray vision for your job site.

GPR technology works by sending a tiny pulse of energy into the slab and recording the strength and time it takes for the signal to return. When the signal encounters an object like a steel bar or a plastic pipe, it bounces back, creating a reading that our technicians can interpret. This process allows us to identify not just the presence of an object, but also its approximate depth and orientation. By performing a subsurface utility mapping of the concrete, we can locate metallic and non-metallic targets, giving you a comprehensive picture before the first cut is ever made. This isn't just about finding obstructions; it's about ensuring every member of your crew can work safely and efficiently.

Rebar, Mesh, and Post-Tension Cables

The most common elements we find are the structural reinforcements that give concrete its strength. This includes rebar (reinforcing steel bars), wire mesh, and post-tension (PT) cables. While hitting rebar can damage your equipment and slow down the project, striking a PT cable is far more dangerous. These high-tension steel strands can erupt from the concrete with explosive force when severed, posing a serious risk to anyone nearby. Our GPR scans precisely locate these elements, allowing you to adjust your core locations to avoid them entirely. We can also determine their depth and spacing, giving your structural engineer the data they need to verify as-built conditions.

Electrical Conduits and Utility Lines

Concrete slabs often contain a network of embedded utilities. We regularly locate electrical conduits, communication lines, and water pipes hidden within or just below the slab. Hitting a live electrical line is a critical safety hazard, while cutting a water pipe can cause extensive flooding and costly damage. Because GPR can detect both metallic and non-metallic materials, we can find PVC conduits and other plastic pipes that older methods might miss. By providing a clear map of these utilities, our utility locating services help you prevent outages, avoid repair costs, and maintain a safe work environment for everyone on site.

Beams and Structural Supports

Beyond standard reinforcement, concrete slabs often conceal larger structural components like embedded beams, thickened areas, and other supports. Cutting into one of these by mistake can compromise the structural integrity of the entire slab or even the building itself. GPR scanning helps identify these critical zones before you begin work. By mapping out the location and dimensions of hidden beams, we give you the information needed to plan your cuts and cores without weakening the structure. This is especially important in renovation or retrofitting projects where original as-built drawings may be inaccurate or unavailable.

Voids and Slab Thickness

Not everything we find is a solid object. GPR is also highly effective at detecting voids, which are air pockets or areas of poor consolidation within the concrete. These voids can be weak points that compromise the slab's load-bearing capacity. Identifying them early allows you to address potential structural issues before they become bigger problems. Additionally, GPR provides a fast and accurate way to measure the thickness of the concrete slab without destructive testing. This data is essential for structural analysis, load calculations, and confirming that the slab meets project specifications.

Why You Need to Scan Before You Cut or Core

Cutting or coring into a concrete slab without knowing what’s inside is a massive gamble for any project. What you can’t see can cause serious harm to your crew, your budget, and the building itself. Every slab is a complex network of structural elements and utilities, from rebar and post-tension cables to electrical conduits and water lines. Hitting any one of these can bring your project to a grinding halt.

That’s why concrete scanning isn’t just a good idea—it’s an essential first step. Using Ground Penetrating Radar (GPR), we can create a detailed map of everything hidden within the concrete before your team ever starts drilling. This simple, non-destructive process transforms guesswork into a clear, actionable plan. It allows you to work with confidence, knowing exactly where it’s safe to cut or core. Think of it as a blueprint for the subsurface, giving you the critical information needed to protect your people, prevent costly damage, and keep your project moving forward without expensive surprises.

Avoid Critical On-Site Safety Risks

Nothing is more important than the safety of your crew. Drilling blindly into concrete puts them at risk of hitting live electrical conduits, which can cause severe electrical shocks or trigger a site-wide power outage. Beyond electrical hazards, other embedded utilities like gas lines or pressurized water pipes can create immediate dangers if ruptured. A GPR scan identifies these hazards before work begins, allowing you to adjust your plans and implement proper safety protocols. It’s a fundamental step in creating a safe work environment and ensuring everyone goes home at the end of the day.

Prevent Costly Utility Strikes

Accidentally striking a utility line is one of the fastest ways to derail a project’s budget and timeline. The immediate repair costs are just the beginning. You also have to account for project downtime while the utility is fixed, which leaves your crew idle and pushes back your schedule. Depending on the utility, you could also face hefty fines and damage your professional reputation. Our private utility locating services use GPR to precisely map out conduits and pipes, so you can avoid these expensive and entirely preventable mistakes.

Protect Structural Integrity

A concrete slab is more than just a flat surface; it’s a carefully engineered structural component. It contains a grid of rebar or a network of high-strength post-tension cables that give it strength and stability. Cutting through one of these critical elements can compromise the integrity of the entire structure, leading to cracks, sagging, or even catastrophic failure. The repairs for this kind of damage are complex and incredibly expensive. Concrete scanning maps out all structural reinforcements, ensuring your core drilling or saw cutting doesn’t weaken the building you’re working on.

Plan Your Project and Protect Your Budget

Knowledge is power, especially in construction. When you know exactly what’s inside the concrete and where it’s located, you can plan your work with precision. A GPR scan allows you to select core locations that are free of obstructions, avoiding the need for last-minute changes or costly relocations. This proactive approach saves significant time and money by preventing unexpected damage and the delays that come with it. The small investment in a concrete scan pays for itself by keeping your project on schedule and your budget intact.

Stay Compliant with Regulations

Creating a safe worksite isn’t just good practice; it’s a requirement. Performing due diligence to identify subsurface hazards is a key part of meeting industry safety standards. A GPR scan provides a clear, documented record that you took proactive steps to locate embedded utilities and structural elements before cutting or coring. This helps ensure your project complies with national safety guidelines, such as those outlined by OSHA for construction, and protects you from potential liability in the event of an incident. It’s a straightforward way to demonstrate a commitment to safety and professionalism.

What to Expect During a Concrete Scan

Knowing what’s inside a concrete slab before you cut, core, or drill is non-negotiable for site safety and project efficiency. But if you’ve never scheduled a scan before, the process might seem like a black box. The good news is that it’s a straightforward, non-destructive process that gives you a clear picture of what’s beneath the surface without causing any damage. It’s all about using advanced technology, like Ground Penetrating Radar (GPR), to see the unseen and map out potential hazards like rebar, conduits, and post-tension cables.

The entire process is designed to be efficient and integrate smoothly into your project timeline. We understand that you have deadlines to meet and budgets to maintain. That’s why our goal is to provide fast, field-ready data that you can use immediately. From the initial site preparation to the final report delivery, every step is handled by expert technicians focused on accuracy and clarity. Think of it as getting a detailed X-ray of your concrete, allowing you to move forward with confidence. This proactive step helps prevent costly utility strikes, protects the structural integrity of the building, and keeps your team safe. Below, we’ll walk through each stage of the process so you know exactly what to expect when our crew arrives on-site.

Preparing the Site

Before we can start scanning, the concrete surface needs to be clear and accessible. This is a simple but crucial first step. Our crew will need you to remove any equipment, materials, debris, or standing water from the scan area. A clean, dry surface ensures the Ground Penetrating Radar (GPR) equipment can make direct contact with the concrete, which gives us the most accurate data possible. We’ll also coordinate with your site manager to confirm the exact boundaries of the area you need investigated so we can focus our efforts precisely where you plan to work.

Performing the Scan

Once the site is ready, our technician will get to work. The primary tool for the job is a GPR unit, which looks a bit like a high-tech lawnmower. The technician systematically rolls the device across the concrete in a grid pattern. As it moves, the GPR antenna sends safe, high-frequency radio waves into the slab. These waves travel through the concrete and bounce off any objects they encounter, like rebar, conduits, or post-tension cables. The antenna receives these reflected signals, which are then sent to an onboard computer that displays the data in real-time. This allows our team to perform an initial utility locating service on the spot.

Analyzing the Data

This is where expertise makes all the difference. The GPR unit shows us data, but it takes a trained eye to interpret what it all means. An experienced technician can distinguish the signature of a rebar grid from that of an electrical conduit or identify a potential void that could compromise the slab’s integrity. They analyze the depth, size, and characteristics of the reflected signals to build a comprehensive picture of what’s hidden inside the concrete. We often mark findings directly on the surface with chalk, paint, or wax crayons, giving your crew an immediate visual guide for their work.

Delivering Your Report

After the fieldwork is complete, we compile all the data into a clear, easy-to-understand report. This isn’t just a raw data dump; it’s an actionable map of the subsurface. Your report will include a detailed drawing or overlay showing the locations and depths of all identified targets within the scanned area. This final deliverable for our subsurface utility mapping becomes a critical tool for your project planning, helping your team drill, cut, or core with confidence. It allows you to adjust plans to avoid costly utility strikes, prevent structural damage, and keep your project on schedule and on budget.

The Technology Behind an Accurate Scan

Getting a clear picture of what’s inside a concrete slab isn’t magic—it’s a combination of sophisticated technology and expert interpretation. While Ground Penetrating Radar (GPR) is the core tool for the job, the accuracy of your scan depends heavily on the quality of the equipment, the software used to process the data, and most importantly, the skill of the technician running the scan. A high-tech GPR unit in untrained hands can still produce misleading results. That’s why we focus on pairing advanced systems with highly experienced field crews to deliver data you can trust. This approach ensures that you’re not just getting a scan, but a clear, actionable map of the subsurface.

How Advanced GPR Systems Work

At its core, GPR is a non-destructive method that lets us see inside concrete without drilling or cutting. The system works by sending a tiny pulse of radio waves from an antenna into the slab. When these waves encounter an object with different properties than the surrounding concrete—like a piece of rebar, an electrical conduit, or even a void—they bounce back to the surface. A receiver records these reflected waves, measuring the time it took for them to travel. Our technicians use this information to pinpoint the exact depth and location of embedded targets, giving you a clear view of potential hazards before you begin work. This process is a key part of our utility locating services.

Creating 3D Images of What's Inside

A single GPR pass provides a 2D slice of the concrete, but the real value comes from creating a comprehensive 3D picture. To do this, our technicians perform a series of scans in a tight grid pattern across the entire area of interest. The data from each scan line is then compiled using specialized software to build a detailed 3D model of the slab’s interior. This gives you a complete and easy-to-understand map showing the precise layout of post-tension cables, conduits, and rebar. This level of detail is essential for planning safe core drilling or saw-cutting locations, and it’s a fundamental part of our subsurface utility mapping process.

Our Methods for Quality Control

The most advanced GPR equipment is only as reliable as the person operating it. Accurate results depend on skilled technicians who can correctly interpret the scan data, and that’s where our team truly stands out. Our field crews undergo extensive training to recognize the subtle signal variations that distinguish a conduit from rebar or identify a void space. We don’t just rely on the machine’s output; we cross-reference our findings with site plans and as-built drawings whenever possible. This meticulous process of data interpretation and verification ensures we deliver clean, engineer-ready results that you can build on with confidence.

What's New in Scanning Tech

GPR technology is constantly evolving, and staying on top of these changes is key to providing the most accurate scans. Recent advances in GPR technology include innovations in antenna design for higher-resolution imaging, AI-assisted signal processing to filter out noise, and more powerful 3D visualization software. At SiteTwin, we are committed to investing in proven, cutting-edge equipment that allows us to see deeper and with greater clarity. By integrating the latest tools with our field expertise, we can tackle complex projects and provide our clients with the most reliable subsurface data available.

Integrating Scanning into Your Project Plan

Bringing a concrete scanning team onto your site isn’t just a last-minute safety check; it’s a strategic move that should be part of your project plan from the beginning. Thinking about scanning early helps you build a more accurate timeline and budget, preventing the kind of surprise discoveries that lead to costly delays and change orders. When you know exactly what’s inside a slab before the coring rig shows up, you can plan your work with confidence.

Integrating scanning means you can map out core locations, trench paths, and anchor points around critical infrastructure instead of reacting to it. This proactive approach protects your crew, your budget, and the structural integrity of the building. It transforms scanning from a simple damage-prevention task into a powerful planning tool. By scheduling a subsurface utility mapping survey early, you get a clear picture of the site, allowing your team to work faster, safer, and more efficiently from day one. It’s about replacing guesswork with data so you can keep your project moving forward smoothly.

When Is the Best Time to Schedule a Scan?

The answer here is simple: schedule your scan before you do any work that involves cutting, coring, or drilling into concrete. This isn't just a suggestion; it's a critical first step for any project involving concrete penetration. Whether you're working on floors, walls, columns, decks, or even sidewalks, a scan should be completed before the tools come out.

Think of it as the essential prep work that sets the stage for a safe and successful project. By identifying rebar, conduits, and other embedded elements beforehand, you can confidently plan your cuts and cores without risking a dangerous utility strike or compromising the structure. Making the scan a standard part of your pre-construction checklist ensures you have all the information you need right from the start.

Understanding the Cost

When planning your budget, it’s helpful to think of concrete scanning as an investment, not just an expense. While professional scanning services can range from $1,000 to $2,000 for a full day, the cost of not scanning is often far greater. A single utility strike can lead to thousands of dollars in repairs, project delays, and potential fines—not to mention the serious safety risks involved.

The price of a scan typically includes the on-site work of an expert technician and a detailed report with clear markings or graphics showing what’s inside the slab. This deliverable is a valuable tool for your entire team. When you get in touch with a scanning provider, they can give you a precise quote based on your site's size and complexity, helping you budget accurately and avoid costly surprises down the road.

How Environmental Factors Can Affect Scans

Ground Penetrating Radar (GPR) is an incredibly powerful technology, but it doesn't work in a vacuum. Certain site conditions can influence the clarity and depth of a scan, which is why having an experienced technician is so important. Factors like the thickness of the concrete, the density of steel rebar or mesh, and even the specific concrete mix can affect how well the GPR signal penetrates the slab.

Additionally, what’s underneath the concrete can sometimes impact the results. For example, scanning a slab-on-grade with highly conductive soil beneath it can be different from scanning an elevated deck. An expert operator knows how to adjust their equipment and interpret the data based on these variables, ensuring you get an accurate picture of embedded targets despite challenging conditions.

Key Safety Protocols to Follow

The most important safety protocol is the one we’ve been talking about all along: always scan concrete before you start any work that involves drilling, cutting, or digging into it. This single step is your best defense against dangerous and expensive damage. Hitting a live electrical conduit or a post-tension cable can have catastrophic consequences for your crew and the structural integrity of the building.

Treating scanning as a non-negotiable part of your safety plan protects everyone on site. It ensures your team isn’t working blind and can proceed with confidence, knowing exactly where it’s safe to cut. This simple but crucial protocol helps you maintain a safe work environment, prevent costly accidents, and keep your project compliant with industry best practices.

How to Choose the Right Scanning Partner

Choosing a concrete scanning partner is a critical decision that directly impacts your project's safety, timeline, and budget. The right team doesn't just show up with equipment; they bring expertise, a commitment to accuracy, and a clear process for delivering the data you need. Not all providers are created equal, and the difference between a quick, inconclusive scan and a thorough, reliable one often comes down to the partner you hire.

Think of it as an investment in risk management. A small upfront cost for a professional scan can save you from catastrophic expenses and delays down the road. When you're vetting potential partners, you're looking for a team that can act as a true extension of your own, providing the subsurface clarity needed to move forward with confidence. Here’s what to look for to ensure you’re working with the best.

Look for These Essential Qualifications

First and foremost, a qualified partner understands that scanning isn't just a preliminary step—it's an essential safety measure. They should operate with a "scan-first" mentality, emphasizing that no cutting, coring, or drilling should ever happen without a clear picture of what lies beneath the surface. Their team should be able to clearly articulate the risks of hitting post-tension cables, live electrical conduits, or other embedded utilities.

Look for a company with a strong safety record and established protocols. They should be fully insured and able to provide documentation. A professional partner will also offer clear, comprehensive reports that go beyond simple field markings, giving your engineers and field crews the detailed information they need. This commitment to safety and clear communication is the foundation of a reliable utility locating service.

Check Their Equipment and Technology

The technology used for a scan is just as important as the team operating it. Your partner should be using modern, high-frequency Ground Penetrating Radar (GPR) systems. GPR works by sending safe radar signals into the concrete; these signals bounce off embedded objects like rebar, conduits, or pipes and return to a receiver. The system then visualizes this data, creating a map of the subsurface.

Ask potential partners about the equipment they use. Are their systems capable of producing high-resolution 2D and 3D imagery? Do they use multiple technologies, like electromagnetic (EM) locators, to confirm findings and identify live power lines? A company that invests in advanced technology is demonstrating a commitment to accuracy and providing the most detailed subsurface utility mapping possible.

Verify Their Field Experience

A GPR scanner is a powerful tool, but it's only as effective as the person using it. Interpreting GPR data is a complex skill that requires extensive training and, most importantly, real-world field experience. An experienced technician can distinguish between different types of materials, identify subtle changes that might indicate a void, and accurately map out congested areas.

An inexperienced operator might misinterpret signals, leading to inaccurate markings and a false sense of security. When vetting a partner, ask about the training and experience of their field crews. How many years have their technicians been scanning concrete? Have they worked on projects similar to yours? Experience is non-negotiable when the structural integrity of a building and the safety of your team are on the line.

Key Questions to Ask Before Hiring

Before you sign a contract, get on the phone and ask some direct questions. The answers will tell you a lot about a company's professionalism, experience, and approach.

Here are a few key questions to start with:

What specific GPR equipment will you use on my site? This shows you understand that technology matters.

Can you describe your team’s training and average level of experience? You want to hear about formal training and years in the field.

What does your deliverable look like? Will you get simple paint on the ground, or will you receive a detailed digital map or report?

Have you worked on projects of a similar scale and complexity? Ask for examples or references if you feel it's necessary.

What are your safety procedures and insurance coverage? Don't skip this. A professional firm will have this information ready.Understanding the Limitations of GPR

Ground penetrating radar is an incredibly powerful technology, but it’s not an X-ray machine. To get the most accurate results for your project, it’s important to understand what can affect the clarity of a scan. GPR works by sending a signal into the concrete and reading the echoes that bounce back. The quality of those echoes depends on the materials in the slab, the depth of the targets, the site conditions, and most importantly, the skill of the technician interpreting the data.

Knowing these limitations isn't about highlighting negatives; it's about setting your project up for success. When you understand the factors at play, you can work with your scanning partner to prepare the site properly and ensure the data you receive is clear, reliable, and ready to build on. A professional crew knows how to work with these variables to deliver the best possible picture of what’s inside the concrete.

How Different Materials Affect Scans

One of GPR’s biggest strengths is its ability to find both metal and non-metal objects hidden in concrete. This means it can locate traditional rebar just as effectively as it can find PVC conduits or electrical lines that other tools might miss. The radar signal reacts differently to various materials, creating reflections that a trained technician can identify.

However, the composition of the concrete and what’s beneath it can influence the scan. For example, concrete with high salt content or slabs poured over soil with dense clay can sometimes absorb the GPR signal, making it harder to see deeper targets clearly. An experienced GPR technician knows how to adjust their equipment settings to account for these materials and get a clean reading.

What Are the Depth Limitations?

The depth GPR can penetrate depends on the antenna frequency being used. Generally, GPR scanners can effectively see up to 18 inches into concrete, which is more than enough for most slab-scanning applications. This allows us to map out rebar patterns, conduits, and post-tension cables within the slab itself.

For deeper targets, technicians use lower-frequency antennas. These can see much deeper but offer less detail, which is a trade-off for locating utilities buried further underground. For concrete slab scanning, we use high-frequency antennas to create a high-resolution image of the embedded elements near the surface. It’s all about using the right tool for the job to ensure you get the precise subsurface data you need.

Do Environmental Conditions Matter?

Yes, site conditions can definitely impact a GPR scan. The most significant factor is moisture. GPR technology doesn't work well in wet or uncured concrete because water is conductive and absorbs the radar signal, preventing it from penetrating the slab. This is why it’s always best to scan concrete after it has fully cured and the surface is dry.

Heavy rebar congestion can also create challenges. If there are multiple layers of dense steel, the signals can become complex and harder to interpret. A skilled analyst can still distinguish individual elements, but it requires a higher level of expertise. Preparing the site by clearing the surface of debris and ensuring it's dry is a simple but critical step for getting accurate results.

Why Expert Data Interpretation Is Crucial

The data from a GPR unit isn’t a simple picture; it’s a complex collection of lines and arcs called a radargram. Turning that raw data into a clear, actionable map requires a trained and experienced technician. Accurate results depend entirely on the ability of the specialist to operate the equipment correctly and, more importantly, interpret what the signals mean.

An expert knows how to tell the difference between a piece of rebar and an electrical conduit based on the signature of its reflection. They can also identify voids, measure slab thickness, and cross-reference the data with site plans to build a complete picture. This human element is what separates a confusing scan from a reliable one, ensuring you can cut, core, or drill with confidence. It’s why having an expert crew on-site is non-negotiable.

Frequently Asked Questions

How long does a typical concrete scan take? The time we spend on-site depends on the size and complexity of the area you need scanned. A small, straightforward area might only take a few hours, while a larger or more congested slab could take a full day. The great part is that you get value almost immediately. Our technicians mark their findings directly on the concrete as they work, so your crew gets a clear visual guide in real-time. A formal report with detailed drawings usually follows shortly after.

Is GPR scanning 100% accurate? Ground Penetrating Radar is incredibly accurate at locating the position and depth of objects within concrete, but it’s important to remember it’s not a perfect X-ray. The clarity of the scan can be affected by factors like high moisture content or extremely dense rebar. This is why the technician's expertise is so critical. A skilled operator knows how to interpret complex data and adjust for site conditions to give you the most reliable picture possible.

Do I really need a scan if I’m only drilling one or two holes? Yes, absolutely. The risk isn’t related to the number of holes you’re drilling; it’s about what a single hole can hit. Severing one post-tension cable or striking one live electrical conduit is all it takes to cause a major safety incident and expensive structural damage. Scanning even a small area is a fast, simple precaution that ensures your one or two cores are placed safely.

Can’t I just rely on the original as-built drawings for my building? Relying solely on as-built drawings is a significant gamble. These documents are often inaccurate from the start and almost never account for changes or undocumented repairs made over the years. GPR provides a real-time map of what is actually inside the concrete right now, not what was planned on paper decades ago. It’s the only way to verify conditions and work with complete confidence.

Is concrete scanning worth the cost for my project? Think of scanning not as a cost, but as an investment in preventing much larger costs. The price of a professional scan is a small fraction of what you would spend on repairing a single utility strike, which can easily run into thousands of dollars when you factor in repairs, project downtime, and potential fines. It’s a proactive step that protects your crew, your budget, and your schedule from expensive and entirely avoidable mistakes.