Ground Penetrating Radar for Utility Locating: A How-To Guide

Calling 811 is a crucial first step for any excavation project, but it’s just that—a first step. The public service only marks public utilities running up to your meter. What about the private water lines, electrical conduits, or fiber optic cables running across your property? Those are your responsibility, and they represent a massive blind spot. Hitting one of these unmarked lines can be just as costly and dangerous as striking a public main. To fill in these critical gaps, you need a more advanced solution. This is where ground penetrating radar utility locating becomes essential, giving you a complete map of both public and private infrastructure.

Key Takeaways

Go Beyond the 811 Call: GPR is essential for locating the private, non-metallic, and undocumented utilities that public services miss, giving you a complete site picture to prevent costly strikes.

Hire an Interpreter, Not Just a Machine: The accuracy of a GPR scan relies on a skilled technician who can translate complex radar signals into a clear, actionable map—their expertise is your most important asset.

Demand a Multi-Method Approach: For the highest level of confidence, ensure your provider combines GPR with other methods like EM locating and existing records to cross-verify findings and eliminate dangerous blind spots.

What is Ground Penetrating Radar (GPR)?

Think of Ground Penetrating Radar (GPR) as a high-tech stud finder for the earth. It’s a non-destructive way to see what’s buried underground without ever breaking ground. Using radar pulses, GPR creates a detailed image of the subsurface, allowing crews to map out utilities like pipes, cables, and conduits before any excavation begins. This technology is a game-changer for anyone planning to dig, trench, or drill, as it helps you avoid the costly and dangerous surprises that 811 often misses. Instead of guessing what lies beneath, you get a clear picture to guide your project safely.

How Does GPR Technology Work?

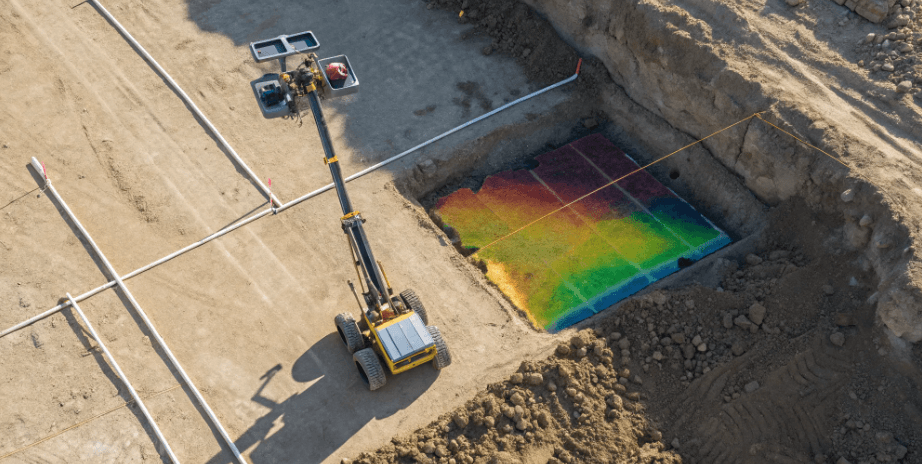

The process is pretty straightforward. A GPR system sends a tiny pulse of electromagnetic energy into the ground. As this energy travels down, it eventually hits an object or a boundary between different soil types—like a PVC pipe surrounded by sand. When that happens, some of the energy bounces back to the surface. A receiver antenna on the GPR unit detects this reflected signal, measuring how long it took to return. By repeating this process in a grid pattern across your site, we can piece together these reflections to create a map of the underground landscape and pinpoint the location and depth of buried utilities.

What's Inside a GPR System?

A typical GPR system looks a bit like a ruggedized lawnmower. It’s made up of a few key parts working together. First, there's the control unit, which is the brain of the operation, processing all the incoming information. Connected to it is an antenna, which is responsible for both sending the radar pulse and receiving the echo that bounces back. Finally, a data acquisition system records everything, turning those raw signals into the images we use to identify what’s below. Our field crews use this equipment to collect precise data directly on your site, ensuring we get a complete picture of the subsurface.

What GPR Can (and Can't) Find

One of the biggest strengths of GPR is its ability to locate both metallic and non-metallic utilities. It can find plastic water lines, fiber optic cables, and concrete storm drains just as easily as it can find metal pipes. However, GPR isn't magic—its performance depends heavily on the ground conditions. It works best in dry, sandy, or rocky soils. In contrast, highly conductive materials like dense, wet clay or soil saturated with salt can absorb the radar signal, making it difficult to see very deep. Understanding these limitations is key to interpreting the data correctly and knowing when to pair GPR with other utility locating services.

Why Use GPR for Utility Locating?

When you’re planning a project that involves breaking ground, what you can’t see is your biggest liability. Guesswork leads to costly utility strikes, project delays, and dangerous accidents. Ground penetrating radar (GPR) is the modern solution for looking beneath the surface before you dig. It’s a powerful tool that gives you a clear, accurate picture of underground infrastructure, helping you move forward with confidence.

See Underground Without Digging

One of the biggest advantages of GPR is that it’s completely non-destructive. The technology allows crews to map underground utilities without digging a single hole. This means you can get a comprehensive view of what’s happening beneath your site while keeping the ground intact. It’s a clean, efficient way to gather critical data, ensuring your project starts on the right foot without unnecessary site disruption or costly exploratory excavation.

Find What Other Methods Miss

Calling 811 is a crucial first step, but it only covers public utilities. It won’t mark the private water lines, electrical conduits, or fiber optic cables running across your property. GPR fills in these critical gaps. It can detect both metallic and non-metallic lines—like PVC, concrete, and fiber—that traditional methods often miss. This makes it an essential part of any comprehensive utility locating plan, especially on complex commercial or industrial sites.

Get Faster, Clearer Results

In construction, time is money. Waiting for outdated or incomplete utility maps can bring your project to a halt. GPR delivers fast, real-time results that can be interpreted directly in the field. A skilled technician can scan a large area quickly and provide immediate feedback on the location and depth of buried infrastructure. This efficiency helps keep your project on schedule by providing the clear, actionable data your team needs to proceed safely.

Avoid Costly Surprises and Rework

Hitting an unmarked utility line is a project manager’s worst nightmare. It can lead to expensive repairs, lengthy downtime, and serious safety hazards. By using GPR to identify potential conflicts early, you can avoid these costly surprises. Finding problems before they happen reduces the need for last-minute design changes and prevents rework. Think of it as an investment that protects your budget, your timeline, and your crew.

Pinpoint the Exact Location of Utilities

Precision is key when you’re trenching near live utilities or planning soil borings. GPR provides highly accurate data on the horizontal position and depth of buried lines. This allows for precise identification, so you know exactly where it’s safe to dig. The detailed information gathered from a scan can be used to create a reliable subsurface utility map, giving your engineers and field crews a clear guide for excavation and design.

What Can GPR Detect Underground?

Ground penetrating radar is an incredibly powerful tool, but it’s not an x-ray machine that gives you a perfect picture of everything underground. Its effectiveness depends entirely on the target you’re looking for and the ground conditions at your site. Understanding what GPR can and can’t see is the first step to a successful scan, helping you know when to deploy it and how to interpret the results to keep your project safe and on schedule.

Think of GPR data as a set of clues. On its own, it's just a series of lines and arcs on a screen. The real value comes from a skilled technician who can read those clues and interpret the story they tell about what’s buried beneath the surface. They can distinguish between a utility line, a large rock, or a dangerous void, turning raw signals into a clear, actionable map. This is where professional subsurface utility mapping transforms complex data into a reliable plan for your excavation or boring project. It’s the difference between having raw information and having a clear, confident path forward for your crew.

Metallic vs. Non-Metallic Utilities

One of the biggest advantages of GPR is its ability to locate non-conductive utilities that other methods, like electromagnetic (EM) locators, can’t find. While EM tools are great for tracing metallic pipes and tracer wires, they’re blind to materials that don’t carry a current. GPR fills this critical gap.

GPR systems can find both metal and non-metal targets, including PVC water lines, plastic gas lines, fiber optic conduits, concrete storm and sewer pipes, and even unmarked graves or voids. This makes it an essential tool for creating a complete picture of a site’s subsurface infrastructure. By using GPR, you can identify those "unlocatable" lines that often cause the most dangerous and expensive utility strikes.

How Deep Can GPR Actually See?

This is one of the most common questions we get, and the honest answer is: it depends. The depth GPR can penetrate is determined by two main factors: the antenna frequency and the soil conditions. Lower frequency antennas can see deeper but provide less detail, while higher frequency antennas offer high-resolution images at shallower depths.

More importantly, the type of soil dramatically affects GPR performance. The radar signal travels easily through dry, sandy, or rocky soil, allowing for deeper penetration. However, heavy, clay-based soils or soils with high moisture content absorb and scatter the GPR signal. Understanding these myths about GPR helps set realistic expectations for what can be found on your specific site.

Telling Different Materials Apart

A GPR unit doesn’t produce a simple photograph of the underground. Instead, it displays data as a series of reflections. When the GPR antenna passes over a linear object like a pipe or cable, it creates a distinct shape on the screen known as a hyperbola—which looks like an inverted U.

A trained technician analyzes the shape, size, and brightness of these hyperbolas to interpret what they represent. The clarity of the hyperbola can indicate whether the target is metallic or non-metallic. For example, a metal pipe produces a very bright, sharp reflection. This expert interpretation is crucial; it’s the skill that turns raw data into a reliable map of underground utilities, as detailed in GSSI's Utility Locating with GPR Handbook.

How Soil Conditions Impact GPR Scans

Soil composition is the single biggest variable affecting the quality of a GPR scan. GPR works by sending a radio wave into the ground and measuring the signal that bounces back. Anything that interferes with that signal will limit the results. The main culprits are materials with high electrical conductivity, which absorb the GPR energy instead of reflecting it.

Soils with high clay content, moisture, or salinity are the most challenging for GPR. In these conditions, the signal weakens quickly, reducing the effective depth and clarity of the scan. Conversely, dry and low-conductivity soils like sand, gravel, and rock are ideal for GPR. That’s why a thorough site assessment before the scan is so important—it helps the GPR provider select the right equipment and techniques for your specific conditions.

GPR vs. Other Locating Methods

Ground penetrating radar is an incredibly powerful tool, but it’s not the only one in the toolbox. Think of it like a doctor using different imaging technologies—an X-ray is great for bones, while an MRI shows soft tissue. Similarly, different utility locating methods have unique strengths. Relying on just one can leave you with dangerous blind spots. The most accurate and reliable results come from combining technologies to build a complete picture of what’s happening underground.

Professional utility locating services rarely depend on a single piece of equipment. Instead, they layer data from multiple sources to cross-reference findings and confirm the location of every asset. This approach minimizes risk and prevents the costly surprises that can derail a project. Understanding how GPR compares to other common methods, like electromagnetic locating and vacuum excavation, helps you know what to ask for and ensures you’re getting a truly comprehensive scan of your site.

Electromagnetic (EM) Locating

Electromagnetic (EM) locating is one of the most common methods for finding conductive utilities. The process is straightforward: a transmitter sends a radio frequency signal through a metallic pipe or a cable with a tracer wire. A receiver then picks up that signal from the surface, allowing a technician to trace the utility’s path with high accuracy.

EM is fantastic for tracing known metallic lines like copper water pipes, steel gas lines, and electrical conduits over long distances. However, its major limitation is that it can’t see non-conductive materials. That means plastic pipes (PVC, HDPE), concrete storm drains, and fiber optic cables without a tracer wire are completely invisible to an EM locator. This is a critical gap that GPR is perfectly suited to fill.

Vacuum Excavation

Vacuum excavation, sometimes called "potholing" or "daylighting," is the only way to be 100% certain of a utility's location and depth. This non-destructive method uses pressurized water or air to loosen the soil, which is then immediately suctioned away by a powerful vacuum. The result is a clean, narrow hole that physically exposes the utility without the risk of damage from a backhoe or shovel.

This isn't a tool for discovery; it's a tool for verification. After GPR and EM have identified a potential utility, vacuum excavation is used at critical points to confirm its exact position before you drill, trench, or excavate. It’s an essential final step for ensuring the safety of your crew and protecting underground infrastructure.

Why a Combined Approach Is Best

Relying on a single technology is a gamble. An EM locator might miss a critical PVC water line, while GPR alone could have trouble interpreting signals in dense, clay-rich soil. This is why a combined approach is the industry standard for comprehensive subsurface utility mapping. By using GPR and EM together, technicians can play to each technology’s strengths.

GPR is used to find both metallic and non-metallic targets, while EM is used to trace conductive lines with precision. When the data from both methods align, it provides a high degree of confidence. When they don't, it signals that more investigation is needed. This layered approach creates a detailed, reliable map that leaves no room for guesswork.

When to Use Each Method

Knowing when to deploy each tool is key to an efficient and safe project. Here’s a simple breakdown:

Use GPR when: You need to find non-metallic utilities, locate unknown lines, or clear an area before excavation. It’s especially effective in sandy or rocky soils and is perfect for identifying potential conflicts before you break ground.

Use EM Locating when: You need to trace a known, conductive utility over a long distance. It’s the go-to method for mapping metallic water mains, gas lines, and electrical cables.

Use Vacuum Excavation when: You need absolute certainty. It should be used to visually confirm the depth and location of critical utilities before any high-risk activity like directional drilling or trenching near a major pipeline.

Getting the Most from Your GPR Scan

A GPR scan is only as good as the team operating the equipment and the process they follow. Simply running a machine over the ground isn’t enough to guarantee accurate results. To ensure you get clear, reliable data that prevents costly strikes and project delays, it’s important to understand what a high-quality GPR survey involves. This means looking beyond the technology itself and focusing on the methodology behind the scan.

Knowing what to look for helps you partner with your locating provider to get the best possible outcome. From the initial site walk to the final report, every step matters. A professional crew will follow a systematic process designed to catch everything possible, integrate different technologies, and deliver findings you can actually use in the field. This isn't just about finding pipes; it's about creating a clear, comprehensive picture of the subsurface so your team can dig with confidence. When you know what to expect from a professional utility locating service, you can ensure you’re getting maximum value and minimizing risk on your project site. It’s the difference between a simple scan and a true subsurface investigation.

Start with a Thorough Site Assessment

The most critical work often happens before the GPR unit is even turned on. A comprehensive site assessment sets the stage for an accurate scan. This involves a detailed walkthrough with your locating technician to discuss the project scope, known utilities, and any potential challenges on site. Clear communication is key. By sharing as-builts, historical records, and firsthand knowledge of the area, you equip your locator with the context needed to interpret the GPR data correctly. This initial collaboration is one of the most important steps in safeguarding your project against surprises and ensuring a safe, efficient excavation.

Ensure Proper Data Collection

Once on-site, a professional technician won’t just wander around randomly. The most reliable method for a GPR survey is a systematic grid search. This involves scanning the area in a tight, organized pattern of perpendicular lines, almost like mowing a lawn. This methodical approach ensures complete coverage and helps the technician build a 3D-like picture of the subsurface in their software. By collecting data this way, they can more easily distinguish between a linear utility line and a random rock or piece of debris. It’s a meticulous process, but it’s the best way to make sure no targets are missed.

Integrate Multiple Data Sources

GPR is an incredibly powerful tool, but it works best as part of a larger toolkit. Relying on a single technology can leave you with blind spots. That’s why we always integrate GPR with other methods, like Electromagnetic (EM) locating, which excels at tracing conductive pipes and cables. We also review all available utility maps and public records before starting. By combining GPR data with EM signals and existing documentation, we create a more complete and verified picture of the underground environment. This multi-faceted approach is the core of professional subsurface utility mapping and the surest way to avoid unexpected conflicts.

Translate Data into Actionable Insights

Raw GPR data looks like a series of abstract lines and curves to the untrained eye. The real skill lies in interpreting these signals accurately. For example, when the GPR antenna passes over a pipe or conduit, it creates a distinct shape on the screen called a hyperbola—an inverted U. An experienced technician knows how to read the characteristics of these hyperbolas to estimate the target’s depth and size. They can also identify patterns that suggest other features, like soil disturbances from previous trenching or potential voids. This expert analysis is what transforms raw data into the actionable intelligence your team needs.

Demand Clear, Field-Ready Reports

The job isn’t finished until you have a clear, usable map of the findings. A professional GPR service should provide more than just paint marks on the ground. You need a final deliverable, such as a site sketch, digital overlay, or detailed written report, that documents everything that was located. This documentation is essential for project planning, stakeholder communication, and future reference. At SiteTwin, we provide clean, engineer-ready results, including precise GPS and GIS mapping that can be dropped directly into your site plans, ensuring the data we collect is immediately useful for your team.

Which Industries Rely on GPR?

Ground penetrating radar isn't a niche technology reserved for a single field. It’s a versatile and essential tool for any industry that needs to understand what’s happening beneath the surface. From bustling construction sites to sprawling university campuses, GPR provides the critical data needed to prevent costly damage, avoid dangerous accidents, and keep projects moving forward. If your work involves digging, drilling, trenching, or building, chances are GPR can make your job safer and more efficient.

The core benefit is simple: GPR gives you a clear picture of the underground without ever breaking ground. This non-destructive approach helps teams intelligently visualize the built world, protecting valuable assets and, more importantly, people. By providing accurate information about existing infrastructure, GPR helps prevent expensive delays and rework. This is why so many sectors have made subsurface utility mapping a standard part of their workflow. Whether you're upgrading a telecommunications network or planning a new campus building, starting with a GPR scan gives you the confidence to build on solid ground.

Construction and Development

For general contractors and developers, surprises are rarely a good thing—especially when they’re buried underground. GPR is a game-changer on construction sites, allowing teams to map out rebar, post-tension cables, conduits, and utilities within concrete or soil before cutting or coring. This insight is crucial for preventing structural damage and avoiding utility strikes that can lead to dangerous situations and costly project shutdowns. By providing a clear map of subsurface conditions, GPR helps teams find problems early, reduce unexpected change orders, and build with confidence. It’s an essential step in ensuring a project stays on schedule and on budget from the very beginning.

Telecommunications

In the world of telecommunications, precision is everything. When installing new fiber optic lines or upgrading existing networks, accidentally striking a buried utility can cause widespread outages and expensive repairs. GPR helps crews identify the exact location of existing communication lines, gas pipes, and water mains before they start trenching. This allows them to plan a safe and efficient path for new installations. By using GPR to create an accurate utility locate survey, telecom companies can protect their valuable assets, prevent service disruptions, and ensure the safety of their field crews during critical infrastructure projects.

Oil and Gas Projects

The stakes are incredibly high in the oil and gas industry, where an accidental utility strike can have catastrophic consequences. On complex sites like refineries and processing plants, the ground is often a tangled web of pipelines, electrical conduits, and control cables. GPR is used to precisely locate and map this dense infrastructure, providing the clear data needed for safe excavation during maintenance, repairs, or expansion projects. This detailed subsurface visualization is a non-negotiable safety measure, helping companies protect their assets, prevent environmental incidents, and ensure the well-being of their workers in these high-risk environments.

Educational Institutions

Facility managers at universities, schools, and hospitals face the unique challenge of maintaining and expanding campuses that have been evolving for decades. The result is often a complex and poorly documented network of underground utilities. GPR is the perfect tool for these environments. It helps locate water lines, steam tunnels, and electrical conduits before starting a new building project or repairing a leak. Because GPR is non-destructive, scans can be performed without digging up manicured lawns or closing off large areas of campus, minimizing disruption to students and staff while ensuring all projects are completed safely.

Road Construction

Before a single lane is paved or a bridge support is drilled, road construction crews need to know what lies beneath the asphalt. Roadways and highways are critical corridors for public utilities, including water mains, sewer lines, and gas pipes. GPR is used to scan the subsurface to locate these utilities and identify potential hazards like voids or deteriorating infrastructure. This allows transportation departments and their contractors to avoid costly and dangerous utility strikes during road widening, resurfacing, or reconstruction projects. The accurate data from a GPR scan helps keep these essential public works projects on track and protects the vital services communities rely on.

What to Expect from a Professional GPR Service

Hiring a professional GPR service is more than just renting a machine and pointing it at the ground. It’s a partnership that brings expertise, advanced technology, and a systematic process to your job site. When you work with a dedicated team, you’re not just getting raw data; you’re getting clear, actionable insights that protect your crew, your budget, and your timeline. A professional service understands that the goal isn't just to find a pipe—it's to deliver a complete picture of the subsurface so you can move forward with confidence. They know what 811 misses and can identify everything from non-metallic lines to unknown utilities that could derail your project.

From the initial site walk to the final report, every step is designed to ensure accuracy and safety. This includes using the right equipment for your specific site conditions, executing a methodical survey plan, and having trained technicians interpret the complex data. They handle the technical details so you can focus on the bigger project. Think of it as an extension of your own team, one that specializes in revealing the unseen hazards lurking just beneath the surface. This approach ensures you get field-ready results without delays, call centers, or outsourcing.

The Right Tools for the Job

You wouldn't use a hammer to drive a screw, and the same principle applies to subsurface scanning. Professional GPR providers invest in the latest equipment because better tools deliver better results. They use high-frequency and low-frequency antennas tailored to your project's needs, whether you're looking for shallow conduits in a concrete slab or deep sewer lines across a large site. This ensures high-resolution imaging and reliable detection of underground utilities. Outdated or consumer-grade equipment can easily miss non-metallic lines or deeper targets, leaving you with a false sense of security. A professional service brings a full toolkit, ensuring they can adapt to any challenge your site presents.

The Survey Process from Start to Finish

A professional GPR scan is a systematic and meticulous process, not a quick pass over the area. The most common and effective method is the grid search approach. A technician will establish a series of survey lines over the designated area, walking the GPR unit back and forth in a tight pattern, almost like mowing a lawn. This ensures complete coverage and allows the technician to collect data from multiple angles. This methodical approach is crucial for accurately mapping the location, depth, and orientation of underground utilities. It’s this attention to detail that transforms a collection of individual readings into a comprehensive subsurface utility map.

From Raw Data to a Clear Map

The GPR unit collects raw data that looks like a series of waves and arcs on a screen—not exactly a user-friendly map. The real magic happens when an experienced technician interprets this data. They analyze the reflections to identify the distinct signatures of different materials like PVC, concrete, or metal. This expertise is what turns abstract data into a clear, field-ready deliverable. Instead of guessing, you get a precise map showing what’s below. This process of utility locating allows you to plan your excavation or boring with confidence, ensuring safety and compliance without ever having to dig blind.

Essential Safety Protocols

Safety is the primary reason for any utility locate, and a professional service makes it their top priority. It starts with clear communication between the GPR technician and your on-site crew to understand the scope of work and potential hazards. A certified locator follows strict industry standards for marking utilities on the surface with paint or flags, creating a clear visual guide for excavators. This thorough process is a crucial step in safeguarding against dangerous and costly utility strikes. It’s not just about finding utilities; it’s about creating a safe work environment for everyone on the project.

Understanding the Cost of a GPR Survey

When it comes to GPR scanning, the cost is influenced by several factors. The price isn't one-size-fits-all because every job site is unique. Key variables include the total square footage of the area being scanned, the complexity of the site, and the type of surface (like soil, asphalt, or concrete). Soil conditions and the number of known or suspected utilities can also affect the time required for a thorough scan. While it might seem like an added expense, a professional GPR survey is an investment in risk management. The cost of a scan is minimal compared to the potential expenses of repairing a damaged fiber optic line or a ruptured water main.

How to Choose the Right GPR Provider

Finding the right GPR provider is about more than just renting a machine—it’s about hiring a partner who can deliver clear, accurate data that keeps your project on track. The quality of a GPR scan depends heavily on the technician’s skill and the quality of their equipment. A great provider translates complex subsurface signals into a simple, actionable map you can trust. Before you hire a team, it’s essential to do your homework to ensure they have the right experience, tools, and processes to protect your site from costly utility strikes.

Verify Their Technical Expertise

GPR is part science, part art. The equipment gathers the raw data, but an experienced technician is the one who interprets it correctly. A skilled operator understands how different soil types, moisture levels, and surface materials affect the GPR signal. They can distinguish between a utility line, a tree root, and random underground debris. When you’re evaluating a provider, ask about their team’s training and field experience. You want a crew that has a deep understanding of subsurface utility mapping and can solve problems on the fly, not just push a machine across your site. Their expertise is your best defense against misidentified targets and incomplete scans.

Ask About Their Equipment

Not all GPR systems are created equal. The technology has advanced significantly, and using modern, high-frequency equipment can make the difference between finding a plastic gas line and missing it completely. Ask a potential provider what kind of GPR units they use. Do they have multiple antennas for different depths and target types? A company that invests in the latest technology is more likely to provide high-resolution imaging and reliable results. Outdated or poorly maintained equipment can lead to noisy data and inaccurate locates, putting your entire project at risk. A professional utility locating service will be transparent about the tools they use and why they’re right for your job.

Confirm Their Service Area

Before you get too far in the conversation, make sure the provider can actually service your project location. Beyond just checking their geographic range, it’s wise to ask if they have experience working in your specific area. Local knowledge is a huge advantage. A team familiar with the region’s soil conditions—be it dense clay, rocky soil, or sand—will know how to calibrate their equipment for the best results. They’ll also be aware of common utility layouts and construction practices in the area. This local insight helps them work more efficiently and accurately, ensuring your GPR scan is tailored to the unique challenges of your site.

Review Their Sample Reports

The final report is the most important deliverable you’ll receive from a GPR provider. Raw GPR data is meaningless to anyone but a trained technician, so you need a final map that is clear, concise, and ready for your field crew to use. Ask for sample reports from past projects. Do their maps clearly distinguish between different types of utilities? Are depths and locations marked in a way that’s easy to understand? The report should be a practical tool that integrates seamlessly into your project plans. A provider who delivers clean, engineer-ready GPS & GIS mapping demonstrates a commitment to providing actionable results, not just a data dump.

Key Questions to Ask Before Hiring

Making the right choice comes down to asking the right questions. Before you sign a contract, have a direct conversation with the provider to gauge their process and professionalism.

Here are a few key questions to get you started:

What is your process for marking utilities in the field?

How do you ensure the accuracy of your findings?

Can you share examples of projects similar to mine?

What safety protocols do your crews follow on-site?

How will the final data be delivered, and in what format?

Engaging with a certified and communicative locator is the best way to safeguard your project. A confident provider will have clear answers that show they are true experts in their field and ready to help you dig safely.

Beyond Locating: Advanced GPR Applications

Ground penetrating radar is known for its ability to find underground utilities, but its capabilities go far beyond that. Think of it as a powerful diagnostic tool that gives you a clear picture of what’s happening beneath the surface, whether you’re dealing with concrete, soil, or asphalt. For general contractors, engineers, and facility managers, this means you can use GPR for much more than just pre-excavation checks.

From mapping complex infrastructure in 3D to identifying potential hazards like voids or buried tanks, advanced GPR applications help you make smarter decisions, prevent costly damage, and keep your projects on track. It’s about moving from simply locating a single pipe to truly understanding your entire site. By using GPR to its full potential, you can get a comprehensive view of subsurface conditions, ensuring the safety and integrity of your project from the ground down.

Create 3D Utility Maps

One of the most powerful applications of GPR is its ability to create detailed 2D and 3D maps of a site. Instead of just a few paint marks on the ground, you get a comprehensive digital model of your entire underground environment. This process, often called subsurface utility mapping, can even produce a "digital twin"—an exact digital replica of your site's buried infrastructure. This gives engineers and project managers a complete visual reference for planning complex installations, avoiding utility conflicts, and managing facility assets over the long term. It’s an invaluable tool for any major construction or renovation project.

Scan Concrete Structures

Before you cut, core, or drill into a concrete slab, you need to know what’s inside. GPR is the go-to method for scanning concrete to locate rebar, post-tension cables, and embedded electrical conduits. It’s a common misconception that GPR provides a perfect, photo-like image of what’s in the concrete. In reality, the GPR screen shows a black-and-white image of reflections that a skilled technician must interpret. This expertise is crucial for accurately identifying targets and ensuring that you can safely penetrate the concrete without hitting a critical structural element or live utility line, preventing expensive repairs and dangerous accidents.

Detect Voids and Sinkholes

Voids and sinkholes are serious geohazards that can compromise the stability of buildings, roads, and other structures. GPR is one of the most effective non-invasive methods for detecting these issues before they become catastrophic failures. The radar waves can identify changes in subsurface density, revealing air gaps, soil washouts, or other anomalies that indicate a developing void. For property managers and civil engineers, using GPR to proactively scan for sinkholes is a critical step in risk management, allowing for timely intervention and repair before a collapse occurs.

Locate Underground Storage Tanks

Finding abandoned underground storage tanks (USTs) is a common challenge, especially on older industrial or commercial properties. These tanks can pose significant environmental risks if they leak. GPR is an ideal tool for locating USTs without the need for extensive and disruptive excavation. The radar can detect the distinct shape and metallic signature of a buried tank against the surrounding soil. This allows environmental consultants and property developers to pinpoint the exact location and orientation of USTs during site assessments, making the process of investigation and removal much more efficient and targeted.

Assess Complex Infrastructure

On large or congested sites like university campuses, hospitals, or industrial plants, the underground environment is often a tangled web of utilities installed over decades. GPR is essential for making sense of this complexity. It helps you intelligently visualize the built world by creating a holistic map of everything below the surface—not just the known utilities, but also old foundations, abandoned lines, and other undocumented features. This comprehensive understanding is vital for planning major site upgrades or new construction, ensuring that new infrastructure can be integrated safely without disrupting critical existing services.

Frequently Asked Questions

Why can't I just rely on the 811 service? The 811 "Call Before You Dig" service is an essential first step for any project, but it has significant limitations. The service only marks public utility lines—the ones owned by utility companies that run up to your property meter. It does not locate any private utilities on your property, such as water lines running to a building, electrical conduits for outdoor lighting, or fiber optic cables connecting different structures. GPR fills this critical gap by mapping out all the infrastructure that 811 is responsible for missing.

Is GPR guaranteed to find every single utility on my property? While GPR is an incredibly powerful tool, it's not an x-ray machine that can see everything perfectly. Its performance is highly dependent on the ground conditions. For example, dense, wet clay soil can absorb the radar signal and make it difficult to see deeper targets. This is why a successful survey relies on more than just technology; it requires an experienced technician who can interpret the data correctly and knows when to combine GPR with other methods, like EM locating, to create the most complete picture possible.

How long will a GPR survey take to complete? The time needed for a GPR scan depends on the size and complexity of the area you need to be cleared. A small, straightforward area for a few soil borings might only take a couple of hours. A large, complex site with numerous known and unknown utilities, like a university campus or an industrial plant, could take a full day or more. A professional provider can give you a more accurate time estimate after discussing your project scope and assessing the site conditions.

What do I need to do to prepare my site for a GPR scan? To get the best results, the GPR technician needs clear access to the area being scanned. You can prepare your site by clearing any vehicles, equipment, or material stockpiles from the survey area. It's also helpful to mow any tall grass or weeds. Most importantly, be ready to share any existing utility maps, as-built drawings, or historical knowledge you have about the property. This information gives the technician valuable context to help them interpret the GPR data accurately.

Can GPR be used on any surface, like concrete or asphalt? Yes, GPR works very effectively on a variety of common surfaces. It can be used to scan through concrete slabs, asphalt parking lots, and of course, soil or grass. The technology is frequently used before concrete cutting or coring to locate rebar, post-tension cables, and electrical conduits embedded within the slab. The type of surface can influence how deep the signal can penetrate, but a skilled technician can adjust their equipment and approach to get clear results in almost any environment.