A Guide to Underground Utility Locating Methods

There is no single magic tool that can see everything underground. Instead, professional locators rely on a specialized toolkit, and knowing which tool to use is the key to an accurate survey. Think of it this way: you wouldn't use a hammer to turn a screw. Similarly, the technology used to find a metal gas line is different from what’s needed to find a PVC water pipe. Understanding the different underground utility locating methods—like Electromagnetic (EM) locating and Ground Penetrating Radar (GPR)—allows you to make informed decisions for your site. This guide will walk you through the strengths and weaknesses of each technique, helping you ensure a complete and reliable picture of the subsurface.

Key Takeaways

- Use multiple technologies to eliminate blind spots: EM locating is perfect for tracing metal pipes, but it can't see non-conductive lines like PVC or fiber. Combining it with GPR is the only way to get a complete and accurate map of all subsurface utilities on your site.

- An expert technician delivers actionable results: Advanced tools produce complex data that requires a trained eye to interpret correctly. A skilled operator is essential for distinguishing actual utilities from other underground clutter, ensuring the map you get is accurate and reliable.

- Account for private utilities beyond the 811 service: The free 811 service only marks public utility mains, not the private lines running throughout your property. A private locate is a critical step to identify everything else and prevent dangerous, costly strikes during excavation.

What Are the Main Utility Locating Methods?

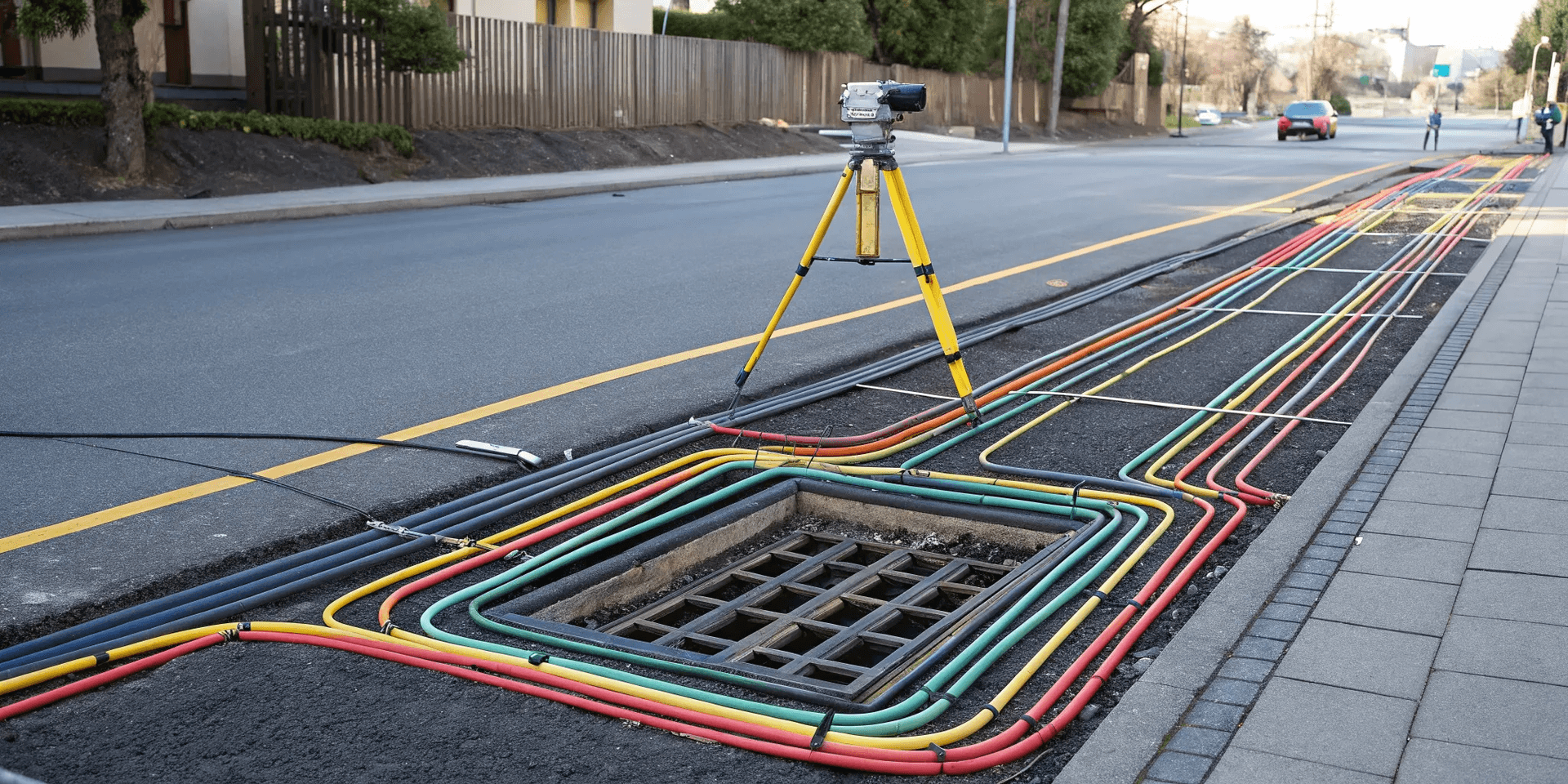

When you need to know what’s buried beneath your job site, you can’t just rely on old maps or guesswork. Professional locators use a few key technologies to find and map underground utilities. Think of it as a toolkit—the right tool depends entirely on the job at hand. The most common and effective methods are Electromagnetic (EM) locating and Ground Penetrating Radar (GPR). EM locating is the go-to for finding conductive pipes and wires. It works by sending a radio signal through a metallic line and using a receiver to trace its path.

For non-metallic lines like PVC, concrete, or fiber optics, Ground Penetrating Radar is the star player. GPR sends high-frequency radio waves into the ground and reads the signals that bounce back, creating a picture of what’s below. In situations where the exact depth and location must be physically confirmed, crews turn to vacuum or hydro excavation. These methods use pressurized air or water to safely dig small holes and expose utilities without the risk of damage from a backhoe. Often, the most reliable results come from combining these methods to get a complete picture of the subsurface.

Why Accurate Utility Locating Matters

Knowing what’s underground before you dig is non-negotiable. First and foremost, it’s a matter of safety. Accidentally striking a gas line or electrical cable can lead to serious injuries, evacuations, and even fatalities. Beyond the immediate danger, hitting a utility can bring your entire project to a halt. The resulting downtime, repair costs, and fines can be staggering—in fact, accidental utility strikes cost billions of dollars in damages each year. Accurate utility locating is a critical investment that protects your crew, your budget, and your timeline from preventable disasters.

Common Types of Buried Utilities

A surprising amount of critical infrastructure runs just beneath our feet. Before starting any excavation, it’s important to consider all the types of utilities that might be present on your site. This includes essential services that keep businesses and communities running. You’ll commonly find lines for natural gas, electricity, and telecommunications, which can include phone, cable TV, and fiber optic cables. Water and sewer lines are also standard, along with storm drains and, in some areas, irrigation systems. Each of these utilities presents a different challenge and potential hazard, which is why identifying and marking all of them is the first step in any safe digging plan.

What Affects Locating Accuracy?

Getting a clear read on underground utilities isn’t always straightforward. Several factors can influence the accuracy of a locate, and a professional crew knows how to account for them. The two biggest variables are the ground conditions and the utility’s material. For example, GPR works beautifully in sandy, uniform soils but can struggle to penetrate dense, wet clay. Similarly, EM locators are perfect for tracing metal pipes but are ineffective for non-conductive materials like plastic or concrete. The depth of the utility and the presence of other underground congestion can also make it harder to get a precise location. This is why choosing the right locating method for your specific site conditions is so important.

How Does Electromagnetic (EM) Locating Work?

Think of electromagnetic (EM) locating as the workhorse of the utility detection world. It’s one of the most common and reliable methods for finding conductive utilities buried underground, and for good reason—it's fast and accurate. The process is straightforward: a transmitter sends out a specific radio frequency, which creates an electromagnetic field around a metallic pipe or cable. This signal travels along the utility line, and a technician on the surface uses a handheld receiver to detect the field and trace the line’s path with paint or flags.

This method is highly effective because it allows crews to map out conductive infrastructure with impressive precision. It’s the go-to technique for locating power lines, communication cables, and metal pipes for water or gas. Because it’s so efficient for these common utility types, EM is a foundational part of nearly every private utility locating project, from simple trenching jobs to complex site developments. However, its effectiveness depends on the type of signal being used and the material of the utility itself, which is why understanding its different modes is so important for getting a complete picture of what lies beneath your site.

Active vs. Passive Detection

EM locating operates in two primary modes: active and passive. In an active locate, the technician intentionally applies a current to the utility line. This can be done through direct connection, where clamps are attached to an accessible point like a valve or transformer, or through induction, where the transmitter is placed on the ground above the suspected line to "induce" a signal onto it. This creates a clean, distinct signal that is easy for the receiver to follow, making it the most accurate EM method.

Passive locating, on the other hand, involves listening for signals that are already present on a utility line. For example, live electrical cables naturally emit their own electromagnetic field, which a receiver can detect without a transmitter. This mode is useful for identifying live power lines quickly or when a direct connection isn't possible, but it’s generally less precise than an active locate.

Estimating Utility Depth with EM

One of the biggest advantages of EM locating is its ability to provide a reliable depth estimate. After tracing a line’s horizontal path, the receiver can calculate how far below the surface the utility is buried. Most professional EM equipment is effective at depths of up to 10-15 feet, which covers the vast majority of buried infrastructure—for instance, most gas lines are only buried three to four feet deep. This depth information is critical for planning safe excavations, as it helps crews know exactly how far down they can dig before needing to proceed with caution or use non-destructive methods. It turns a simple line on the ground into a three-dimensional piece of data you can actually use for planning.

Common Limitations of EM Locating

While EM locating is excellent for finding conductive materials, it has one major blind spot: it cannot detect non-metallic utilities. Pipes made from plastic (PVC), concrete, or clay do not conduct electricity, so they can’t carry the signal from an EM transmitter. The only exception is if the utility was installed with a tracer wire—a thin metal wire buried alongside the pipe specifically for locating purposes. If there’s no tracer wire, or if it’s been broken over time, an EM locator won’t see the utility at all. This is why a comprehensive subsurface utility mapping plan often requires multiple technologies, like GPR, to find what EM might miss and give you a complete view of your site.

What is Ground Penetrating Radar (GPR)?

When you need to find non-metallic lines like PVC, concrete, or fiber optics, or locate unknown utilities without a tracer wire, Ground Penetrating Radar (GPR) is the tool for the job. Unlike electromagnetic (EM) locators that rely on conductive materials, GPR acts like an ultrasound for the ground. It provides a visual cross-section of the subsurface, making it an incredibly powerful technology for creating a complete picture of what lies beneath your site.

GPR is one of the most advanced subsurface utility mapping methods available. It excels at identifying not just utilities, but also other buried objects like old foundations, rebar within concrete, and even underground storage tanks. When combined with other methods, it helps create a comprehensive map that prevents costly surprises during excavation. Think of it as the key to seeing the unseen and verifying what other tools can only suggest.

How GPR Scans the Subsurface

GPR works by sending high-frequency radio waves into the ground from a surface antenna. When these waves encounter a buried object or a change in material, they reflect back to the surface, where a receiver records them. The system measures the time it takes for the signal to travel down and back, which helps determine the object's depth. As the technician moves the GPR unit across the surface, it collects hundreds of these readings to build a detailed, real-time image called a radargram. This allows a skilled operator to visualize a slice of the underground and identify the precise location of pipes, cables, and other potential obstructions before you ever break ground.

How Soil Conditions Affect GPR Performance

While GPR is highly effective, its performance is directly influenced by the ground itself. The radio waves travel best through dry, sandy, or low-conductivity soils. In contrast, dense materials like heavy clay, wet soil, or salty ground can absorb and weaken the signal, limiting its penetration depth and clarity. This is why a pre-survey site assessment is so important. An experienced technician will understand these limitations and know how to adjust their approach. Understanding the local soil composition is a key part of planning a successful GPR scan and ensuring the data you receive is as accurate as possible.

Interpreting GPR Data Correctly

The data from a GPR unit is not a simple photograph—it’s a complex series of arches and reflections that requires a trained eye to decipher. An inexperienced operator can easily misinterpret these signals, leading to an inaccurate locate. For example, a large rock could be mistaken for a utility line, or a faint signal from a deep target could be missed entirely. Effective detection often depends on the object's size relative to its depth. This is why the technician's skill is just as important as the equipment itself. Our expert crews are trained to analyze GPR data accurately, distinguishing true utilities from other subsurface clutter to deliver clean, field-ready results you can trust.

Other Locating Methods to Know

While Electromagnetic (EM) and Ground Penetrating Radar (GPR) are the primary tools for most subsurface investigations, they aren't the only options available. A comprehensive approach to utility locating often involves a combination of technologies, especially when dealing with challenging site conditions or non-traditional utility materials. Think of it like a doctor using different diagnostic tools to get a complete picture of a patient's health.

Professional locators keep several other methods in their back pocket to verify findings, locate tricky targets, and ensure the highest degree of accuracy. Understanding these techniques can help you appreciate what goes into a thorough site scan and why a multi-method strategy is often the safest bet. From using sound waves to physically exposing a line for visual confirmation, these complementary methods play a crucial role in preventing dangerous and costly utility strikes. A truly professional utility locating service will know exactly which tool to use for the job at hand.

Acoustic Detection

Sometimes, you need to find a utility that’s invisible to other technologies. Acoustic detection is a specialized method that works by sending sound waves into the ground and listening for the echoes that bounce off a pipe. It’s particularly effective for locating non-metallic or non-conductive lines, like plastic water mains or PVC conduits, that EM locators can’t pick up.

This technique is a great problem-solver when GPR struggles due to difficult soil conditions. Because it relies on sound, it can often succeed in areas with dense clay or wet soil where radar signals might scatter. While not as common as EM or GPR, acoustic detection is an invaluable tool for confirming the location of plastic pipes and avoiding a blind excavation.

Radio Detection

If you’ve heard people in the industry talk about "radio detection," they are most likely referring to the same core technology as Electromagnetic (EM) locating. This is the most common and foundational method for finding conductive utilities. The process involves using a transmitter to send a specific radio frequency through a metallic pipe or a tracer wire.

A handheld receiver is then used to scan the area, picking up the radio signal as it radiates from the buried line. The receiver interprets the signal strength to pinpoint the utility's horizontal position and estimate its depth. It’s the go-to method for tracing known metallic lines like copper, steel, and cast iron, forming the backbone of nearly every subsurface utility mapping project.

Vacuum and Hydro Excavation (Potholing)

When you need 100% certainty about a utility’s exact depth and location, nothing beats visual confirmation. Vacuum and hydro excavation, often called "potholing" or soft digging, are methods used to safely expose buried utilities. Instead of using a backhoe, which could easily damage a line, these techniques use focused air or water pressure.

Hydro excavation uses high-pressure water to break up soil, which is then suctioned into a debris tank. Vacuum excavation uses compressed air to loosen the soil before vacuuming it away. Both are precise, minimally invasive ways to dig small test holes, allowing crews to physically see and measure a utility. This is the only way to achieve the highest accuracy standard, known as Quality Level A, and is essential for final design and pre-construction verification.

Essential Safety Protocols and Best Practices

Safety isn't just a box to check—it's the foundation of every successful excavation project. A single mistake can lead to costly damages, serious injuries, or worse. Following a clear set of protocols protects your crew, your project timeline, and the critical infrastructure buried just beneath the surface. These best practices aren't complicated, but they are non-negotiable for any team working around underground utilities. From initial planning to emergency preparedness, every step is designed to prevent accidents and ensure a smooth, safe dig.

Plan Your Survey Before You Dig

The first rule of any excavation is to know what you're digging into. Before a single shovel hits the ground, you must have a complete picture of the subsurface. This always starts with calling 811, but for commercial, industrial, or dense urban sites, that’s just the beginning. Public utility locators only mark lines they own up to the meter. Private lines—including power to a security gate, fiber optic cables between buildings, or old, abandoned pipes—won't be marked. That's why a comprehensive private utility locating survey is essential. It fills in the gaps left by the 811 system, giving your team the complete and accurate data needed to dig with confidence.

Decode Marking Standards and Color Codes

Once a locate is complete, the ground will be marked with paint or flags. These colors are a universal language for excavators, and knowing what they mean is critical. The American Public Works Association (APWA) has a uniform color code that designates specific colors for different utility types. For example, red indicates electric power lines, yellow is for gas or oil, blue is for potable water, and orange signifies communication lines like fiber optics. Your entire crew should be familiar with these colors so they can immediately recognize the type of infrastructure they're working near and take the appropriate precautions for each.

Respect the Tolerance Zone

The paint and flags on the ground mark the approximate location of a utility, not its exact position. This is why regulators establish a "tolerance zone," which is a designated area on either side of the marked line. While the exact width varies by state, it's typically 18 to 24 inches. Within this zone, you should never use mechanized equipment. The only safe way to excavate here is by using soft-digging techniques, like hand digging with a shovel or using vacuum excavation. This allows you to visually confirm the utility's precise depth and location before bringing in heavy machinery, preventing a potentially catastrophic strike.

Establish Emergency Procedures

Even with the best planning, accidents can happen. Your team must have a clear, rehearsed emergency plan in place before any work begins. If a utility line is struck, the first step is to stop all work immediately. If it's a gas line, evacuate the area to a safe, upwind location and eliminate any ignition sources. From a safe distance, call 911 and then the utility owner's emergency number. Do not attempt to repair or stop a leak yourself. Having these steps clearly defined and understood by every person on-site ensures a quick, calm, and effective response that protects lives and minimizes damage.

How to Choose the Right Method for Your Project

Selecting the right utility locating method isn't about picking the "best" tool—it's about choosing the best tool for the job. Every site is unique, with its own set of challenges hidden just beneath the surface. A method that works perfectly on one project might fall short on another. The key is to evaluate your specific needs and site conditions to build a locating strategy that delivers clear, reliable results.

Making an informed choice from the start prevents costly surprises down the road. Factors like the type of utilities you expect to find, how deep they are buried, and the ground conditions all play a critical role. By understanding these variables, you can ensure your team uses a combination of technologies that provides a complete picture of the subsurface, protecting your crew, your budget, and your timeline. A thoughtful approach is the foundation of any successful excavation project.

Assess Your Site Conditions

Before any equipment comes out of the truck, a thorough site assessment is crucial. The ground itself can have a major impact on which locating methods are most effective. For example, ground penetrating radar (GPR) performance can be limited in clay-heavy or saturated soils, while electromagnetic (EM) locating is less affected by soil type. You also need to consider surface-level obstacles. Is the area covered in asphalt, concrete, or grass? Is it a wide-open field or a congested urban corridor packed with other infrastructure? Finding underground utilities is essential for safety, preventing expensive damage, and avoiding service outages during your project. A clear understanding of your site helps determine the best approach.

Consider the Utility's Material

The material of the utility you're trying to find is one of the most important factors in choosing a locating method. Electromagnetic (EM) locating is excellent for finding conductive materials like copper and steel pipes. However, it cannot find pipes made of non-metal materials like plastic, concrete, or clay, unless they have a tracer wire installed alongside them. This is a huge blind spot if you’re working on a site with water lines or modern fiber conduits. In these cases, GPR becomes essential. It detects changes in the subsurface, allowing it to identify non-conductive pipes that EM locators would miss entirely. That's why our utility locating services often start with this critical question.

Factor in Depth Requirements

How deep do you need to see? The answer will help guide your choice of technology. Electromagnetic locators are highly effective for many common utilities, typically working well up to 10-15 feet deep. Since most gas lines are buried at 3-4 feet, EM is often a reliable tool for the job. However, if your project involves deeper targets like sewer mains, storm drains, or specialized conduits, you may need a different approach. GPR can often detect utilities at greater depths, though its exact range depends on the soil conditions and the antenna frequency used. Defining your depth requirements upfront ensures your locating team brings the right equipment to capture the data you need for safe excavation.

The Benefits of a Multi-Method Approach

Relying on a single technology can leave you with an incomplete picture of the subsurface. The most effective way to get accurate, comprehensive results is to combine methods. Using both GPR and EM tools together is the best way to find all underground utilities. This strategy leverages the strengths of each technology while compensating for their individual weaknesses. For instance, an EM locator can quickly trace a known metallic line, while a GPR scan can identify nearby non-metallic pipes, voids, or other unexpected features. This integrated approach is the core of a professional subsurface utility mapping plan and is the surest way to avoid dangerous and costly surprises once digging begins.

What to Expect from a Professional Locating Service

When you hire a professional utility locating service, you’re not just paying for paint on the ground. You’re investing in risk mitigation, project efficiency, and the safety of your crew. Unlike the basic service provided by 811, a private firm is your partner in understanding the complete subsurface picture of your site. They work for you, focusing on your project’s specific boundaries and needs.

A professional service moves beyond just public mains and identifies everything from private electrical lines running to a security gate to abandoned pipes that could complicate an excavation. They provide a detailed, comprehensive map of what’s below, giving your team the confidence to dig safely. This level of detail is crucial for avoiding costly strikes, redesigns, and dangerous accidents. Expect clear communication, detailed reports, and a team that understands the stakes of your project.

Using the Right Equipment

A professional crew arrives with a full toolkit, not just a single piece of equipment. The two workhorses of the industry are Electromagnetic (EM) locators and Ground Penetrating Radar (GPR). EM locators are fantastic for tracing conductive pipes and cables by sending a radio signal through them. GPR complements this by sending radar pulses into the ground, allowing it to detect non-metallic lines like PVC and concrete, as well as other buried objects. A professional service knows which tool to use and when, often combining methods to confirm findings and create a more reliable map of your site’s subsurface utilities.

Why Operator Qualifications Matter

The most advanced GPR or EM locator is only as good as the technician operating it. An experienced operator can interpret ambiguous signals, distinguish a utility line from rebar or buried debris, and adjust their technique based on site conditions. Trained and certified locators understand the physics behind their tools and know how to cross-verify findings to ensure accuracy. They can identify old or undocumented lines that might not appear on any records. When you vet a service, ask about the training and field experience of their crew. This expertise is what turns raw data into actionable intelligence for your project.

Look for Industry Certifications

Professionalism in this field is defined by established standards. A key benchmark to look for is adherence to the guidelines set by the American Society of Civil Engineers (ASCE). Specifically, the ASCE 38-22 standard outlines the process for Subsurface Utility Engineering (SUE). This framework establishes different quality levels for utility data, ensuring that the information you receive is reliable and appropriate for your project's design and excavation phases. A firm that follows these standards demonstrates a commitment to quality and professional accountability, which is exactly what you need when dealing with hidden infrastructure.

Ensure On-Site Quality Control

A professional locating job doesn’t end when the scanning is done. Quality control should be an active, on-site process. This means the crew takes steps to verify their findings, often by using a second technology to confirm the location of a critical utility. They should also communicate clearly with your site manager, walk the area to explain the markings, and answer any questions before they leave. The goal is to deliver clean, field-ready data that your team can trust without hesitation. This focus on comprehensive site evaluation before excavation begins is the best way to minimize surprises and keep your project on track.

The Risks of an Inaccurate Locate

Getting a clear picture of what’s underground isn’t just a box to check—it’s one of the most critical steps in any project. An inaccurate or incomplete utility locate can introduce serious risks that ripple through your entire operation, affecting everything from crew safety to your bottom line. When you break ground, you’re not just moving dirt; you’re interacting with a complex network of critical infrastructure. Understanding the potential consequences of a utility strike is the first step toward preventing one. From physical dangers to financial and legal fallout, the stakes are incredibly high.

On-Site Safety Hazards and Accidents

First and foremost, an inaccurate locate puts people in danger. Finding underground utilities before digging is crucial to prevent accidents, injuries, and even deaths. Every year in the United States, there are more than 450,000 utility strikes, many of which result in serious harm. Hitting a gas line can cause an explosion, while striking a high-voltage electrical cable can be fatal. These aren't abstract risks; they are real-world dangers that your crew faces every day. Ensuring a safe work environment is the most important part of any job, and it starts with knowing exactly what lies beneath the surface before the first shovel hits the ground.

Costly Project Delays and Rework

Beyond the immediate safety concerns, a utility strike is a surefire way to derail your project's schedule and budget. Each year, billions of dollars are spent repairing utilities that were hit by accident, with the total economic cost of strikes reaching up to $30 billion. A single incident can halt all work on-site, leading to expensive crew downtime, emergency repair costs, and fees for service interruptions. The resulting rework can set your timeline back by days or even weeks, potentially triggering late-completion penalties and damaging your relationship with the client. An accurate locate is an investment that pays for itself by preventing these costly and frustrating delays.

Damage to Critical Infrastructure

When you dig on your site, you’re working around the essential infrastructure that powers our communities. Hitting these lines can be dangerous, costly to fix, and cause major service disruptions that affect far more than just your project. Severing a fiber optic cable can knock out internet and phone service for local businesses and residents, while damaging a water main can lead to flooding and service outages. Protecting this infrastructure is a shared responsibility. A comprehensive subsurface utility mapping plan ensures your project proceeds smoothly without causing a headache for the entire neighborhood.

Potential Legal Consequences

Finally, a utility strike can expose your company to significant legal and financial liability. While you should always call 811 before you dig to locate public utilities, that call doesn't cover private lines on your property and may not provide the level of detail needed for complex projects. Digging without a complete and accurate understanding of the subsurface is the most common cause of natural gas emergencies and other serious incidents. A strike can result in hefty fines from regulatory agencies, expensive lawsuits from damaged parties, and lasting damage to your company’s reputation. Proper due diligence isn't just a best practice—it's your best defense.

How to Manage Compliance and Documentation

Managing the paperwork might not be the most exciting part of a project, but when it comes to subsurface utilities, it’s one of the most critical. Proper documentation isn’t just about checking boxes for compliance; it’s about creating a reliable record that protects your team, your timeline, and your budget. From knowing the law to keeping meticulous records, a solid documentation strategy ensures that the valuable data you collect today remains useful for years to come. It transforms a one-time locate into a permanent asset for your site, preventing future guesswork and minimizing risk for every project that follows.

Know the Legal Requirements

Before a single shovel hits the ground, your first step is always the same: call 811. This isn't just a suggestion—it's the law. This national service coordinates with public utility operators to mark their lines on your property, typically for free. Hitting a public gas, water, or electric line can lead to dangerous situations, expensive repairs, and major project delays. Remember that 811 only covers public utilities. For anything on private property—like lines running between buildings or to a security gate—you'll need a private locating service to get the full picture.

Follow Proper Documentation Standards

Once you have your data, it’s important to document it in a way everyone on the project can understand. The industry benchmark for this is the ASCE 38-02 standard, established by the American Society of Civil Engineers. This standard provides a clear system for classifying the quality of subsurface utility data, from basic record research (Quality Level D) to precise horizontal and vertical location data confirmed by exposure (Quality Level A). Adhering to these standards ensures that engineers, surveyors, and contractors are all speaking the same language, which reduces the risk of misinterpretation and costly mistakes.

Best Practices for Keeping Records

Think of your utility locate data as a long-term asset. Keeping detailed, organized records of every locate is one of the smartest things you can do for your property. A well-documented utility map saves an incredible amount of time and money on future projects, from maintenance and repairs to new construction. Instead of starting from scratch every time, your team can refer to a reliable historical record. This is where professional subsurface utility mapping creates lasting value, turning field data into a clean, engineer-ready digital twin of your site’s underground infrastructure.

Verify Finds with Multiple Methods

No single locating technology is foolproof. Soil conditions, utility material, and depth can all affect accuracy. That’s why verifying finds with multiple methods is a non-negotiable best practice. For example, an electromagnetic (EM) locator might pick up a metallic pipe, while Ground Penetrating Radar (GPR) can confirm its location and identify a nearby non-metallic conduit that EM missed. Combining different proven technologies with the expertise of skilled technicians provides the most reliable results. Your documentation should always note which utility locating services and methods were used, giving you a complete and trustworthy picture of what lies beneath.

Frequently Asked Questions

I already called 811. Why do I need to hire a private utility locator? Calling 811 is an essential first step, but it's important to know its limits. The 811 service only marks public utility lines—the ones owned by utility companies that run up to your property's meter. Any lines that go past that point, like electrical wiring to a parking lot light, fiber optic cables connecting two buildings, or water lines for an irrigation system, are considered private. A private locating service is hired to find and map all of these private utilities that 811 is not responsible for, giving you a complete picture of what's buried on your site.

Can't you just use GPR to find everything underground? While Ground Penetrating Radar (GPR) is an incredibly powerful tool, it's not a magic wand that can see everything perfectly in all conditions. Its performance depends heavily on the soil. In dense, wet clay, for example, the radar signal can weaken, making it difficult to get a clear picture. For conductive utilities like metal pipes and electrical cables, electromagnetic (EM) locating is often faster and more precise. The most reliable results come from using both methods together, allowing them to cover each other's blind spots.

What happens if a utility is too deep or made of a material that's hard to detect? This is where visual confirmation becomes necessary. When a critical utility can't be pinpointed with confidence using surface-level tools, the safest approach is to physically expose it. Methods like vacuum or hydro excavation, also known as potholing, use pressurized air or water to gently remove soil in a small area. This allows crews to see the utility with their own eyes, confirming its exact depth and position without the risk of damage from a backhoe or excavator.

How can I be sure the markings on the ground are accurate? The accuracy of a locate comes down to two key factors: the quality of the equipment and the skill of the person using it. A trained technician knows how to interpret the complex signals from GPR and EM locators, distinguishing a real utility from a buried rock or other debris. They also understand how to adjust their approach based on site conditions and will often use multiple methods to cross-verify their findings. A professional service delivers confidence by combining advanced technology with experienced field expertise.

What's the single biggest mistake to avoid before starting an excavation project? The biggest mistake is making assumptions. This includes assuming that old site plans are accurate, that the 811 service marked every line on your property, or that an empty lot has nothing buried beneath it. Every project should start with a fresh, comprehensive survey to verify what is actually underground. Taking the time to get a complete picture before you dig is the most effective way to prevent dangerous accidents, costly damages, and major project delays.